What is the function of the brake system?

Functions of the brake system in vehicles;

- Reducing the speed of the vehicle,

- Stopping the vehicle,

- To stabilize the stationary vehicle in place (handbrake).

What is brake system?

The brake system is one of the most important active safety systems that allows the vehicle to slow down or stop safely.

How does the brake system work?

Braking is the process of converting the kinetic energy (movement energy) of the vehicle in motion into heat energy. The motion energy of the vehicle turns into heat energy generated by the friction of the pads against the disc and the vehicle slows down or stops.

When the driver presses the brake pedal, this pushing movement is transmitted to the brake servo by a push rod, the brake pedal connection works like a lever and the thrust force is increased and transmitted to the brake servo. The brake booster is transmitted to the piston rod in the brake main center just in front of it, increasing this thrust of the driver even more. There is hydraulic brake oil in the brake main center.

The pistons in the brake center pressurize the hydraulic fluid (with greater force) and transmit it to the brake cylinders in the wheels and the pistons in the calipers, via hydraulic pipes and hoses, with the pushing movement of the driver by pushing the pedal and further strengthened by the servo.

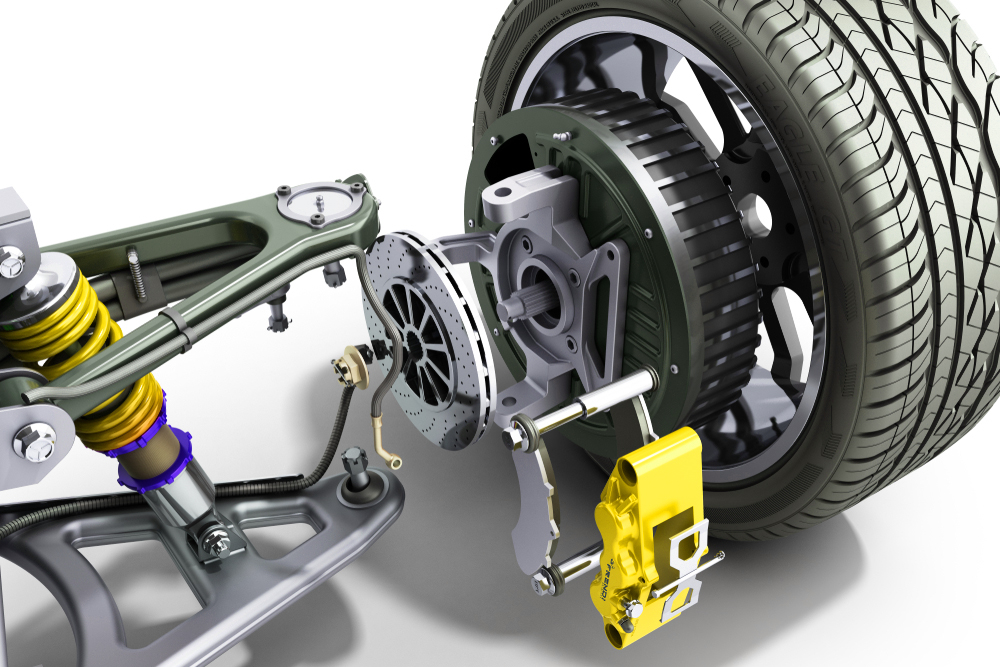

Disc brakes have brake caliper. Pressurized hydraulic fluid pushes the piston in the cylinder in the caliper towards the disc, there is a brake pad in front of the piston, by the brake pad rubbing against the disc, the disc fixed to the wheel center slows down, the wheel slows down or stops. Drum brakes have a wheel brake cylinder inside the drum.

The operation of the hydraulic brake is based on the pascal principle.

Electronic equipment has been added to the hydraulic brake systems with the developing technology and its operation has been improved. ABS, ASR, ESP etc. are additional systems. The ABS system is offered as standard in new generation vehicles and the use of the ESP system is becoming very common. Along with these systems, many sensors and activators have been added to the brake system.

In today's middle class passenger cars and light commercial vehicles, disc brakes are generally used on the front wheels and drum brakes are used on the rear wheels. However, as of 2016, the use of disc brakes on 4 wheels has become increasingly common in vehicles produced.

Air (pneumatic) brake systems are used in vehicles such as trucks and buses carrying heavy loads.

What are the Types of Brake System?

Brake systems can basically be examined under 3 main headings, these are Hand Brake, Service (foot) Brake and Auxiliary Brake Systems.

HANDBRAKE

- Mechanical Handbrake

- Electric Assisted Parking Brake (See: Electronic Parking Brake)

SERVICE BRAKE (FOOT BRAKE)

- Mechanical Brakes (Not Used Today)

- Classic Hydraulic Brakes (No hydrowax, not used today)

- Vacuum Assisted Hydraulic Brakes (The most widely used type today)

- Air Assisted Hydraulic Brakes

- Air Brakes (For Trucks and Buses)

- Electric Brakes

AUXILIARY BRAKE SYSTEMS

- Abs Brake System

- Traction (Skid) Control System (ASR – TRC – TCS)

- Electronic Stability System (ESP – ESC – VSC)

- Electronic Brake Distribution System (EBD)

- Wear Free Brake Systems (Retarder - Exhaust Brake - Engine Brake)

HYDRAULIC BRAKE SYSTEM

What are the Basic Parts of the Hydraulic Brake System?

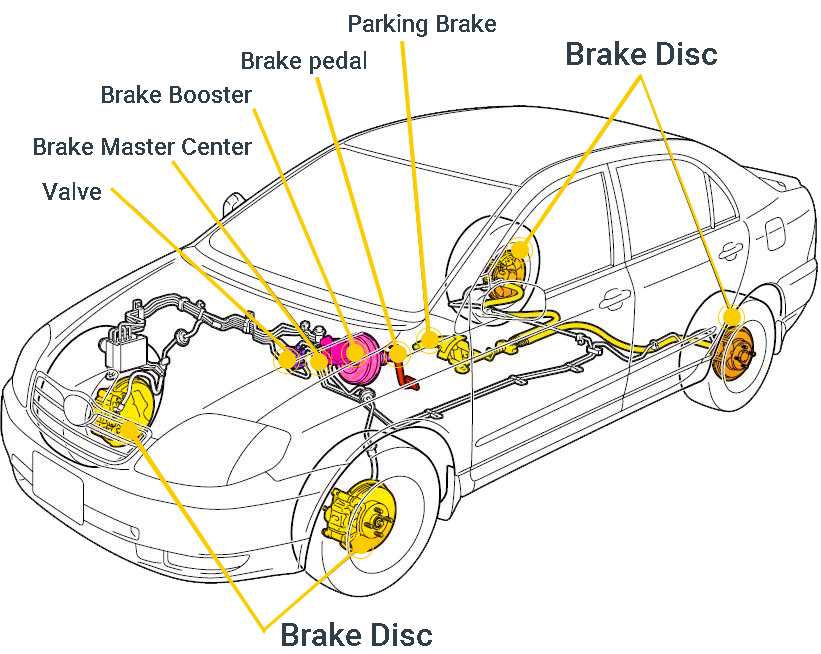

General parts of the brake system: brake pedal, brake booster (westinghouse), main brake center, Hydraulic valve module, brake pipes and hoses, brake discs, brake drums, calipers, wheel brake cylinders, brake pads.

Working Principle of Hydraulic Brake System

The brake system converts the vehicle's motion energy into heat energy by friction in the brake mechanism, allowing the vehicle to slow down or stop. The hydraulic brake system is based on the logic of using hydraulic fluid in the brake system, increasing the force generated in the brake pedal with the pascal principle and transmitting it to the wheel cylinders, thus converting the little pushing force created by the driver's foot on the brake pedal into a friction force that can easily stop the vehicle with the pads.

In drum or disc brake mechanisms on wheels, friction caused by pressurized hydraulic fluid pushing the piston and pushing the pad to the disc or drum slows or stops the wheel. As the wheel slows down, the tire on it rubs against the road, slowing and/or stopping the vehicle. The thing that slows-stops the vehicle is the coefficient of friction between the tire and the road. For more information (See: Braking Force-Friction Coefficient)

What actually happens is that the mechanical movement generated by the pedal is converted into an increased hydraulic pressure, this high hydraulic pressure being converted back into a strong mechanical action in the wheel brake mechanism. Low force -- > large hydraulic pressure (pascal principle) -- > braking at the wheel with large force.

Brake System Parts and Their Functions

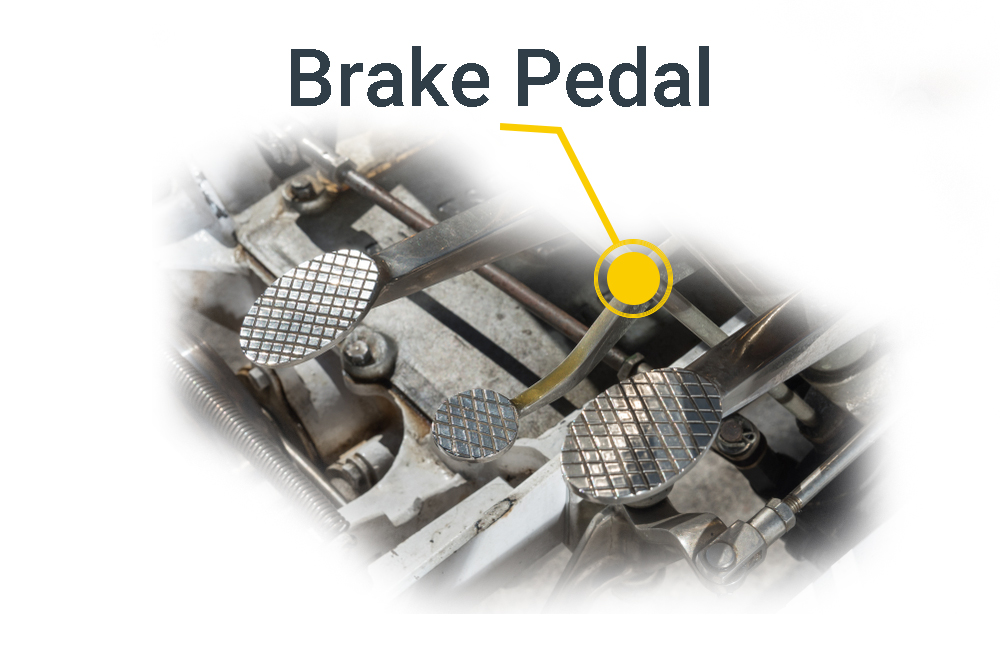

Brake Pedal: In the hydraulic brake system, the braking dosage and pushing force are created by the driver with the brake pedal. The brake pedal is in the form of a lever and transmits it as a pushing force to the brake servo, increasing approximately 5 times the pedal force pressed by the foot.

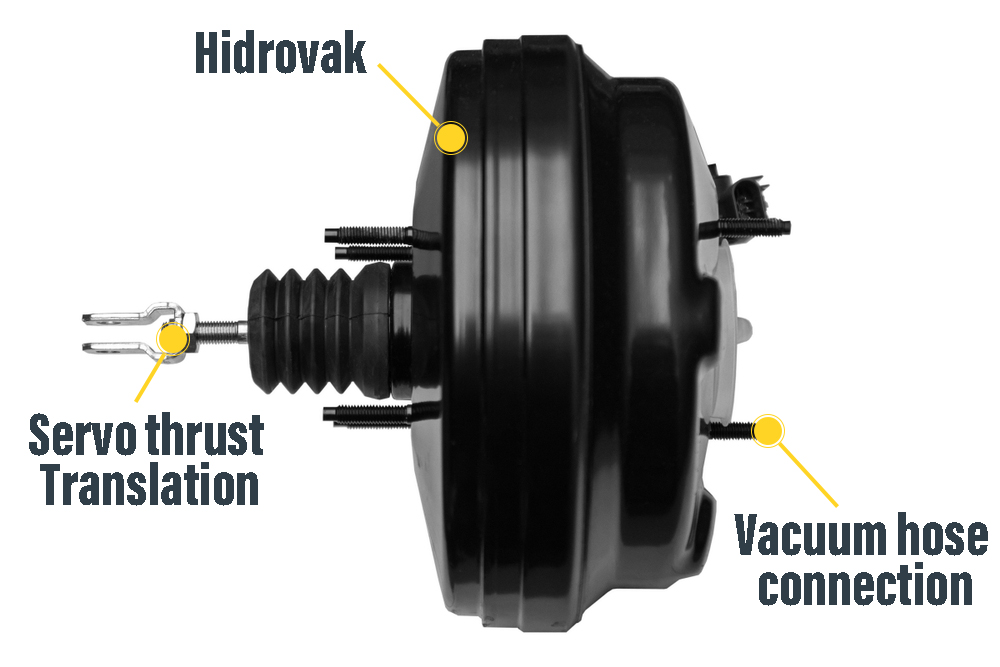

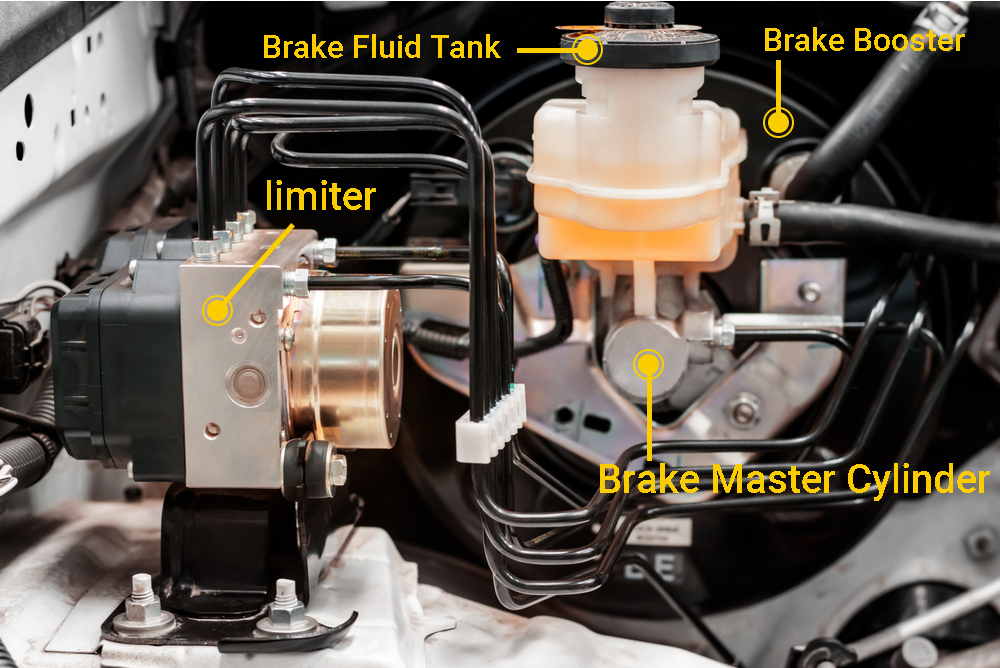

Brake Servo - Hydrovac (Westinghouse): The pushing force generated in the brake pedal is increased by the brake servo and transmitted to the brake main center. The brake booster vacuum increases the pushing force of the brake pedal. For more information (Refer to: Brake Booster Operation and Role) (Refer to: Brake Booster Malfunction)

Brake Main Cylinder: The brake main center is located just in front of the brake booster. Function of the brake main cylinder: The thrust force from the brake booster is converted into hydraulic pressure in the brake main cylinder. This hydraulic pressure is sent to the brake calipers on the wheels (brake cylinders if drummed) via two brake outlet pipes: front and rear wheels or right front left rear – left front right rear. For more information (See: Brake Main Cylinder)

If the vehicle has an ABS brake system, these two brake lines coming out of the brake center are connected to the ABS hydraulic module input. From here, hydraulic brake pressure is sent to each wheel separately.

Brake Fluid Box (Reservoir): The brake fluid hydraulic box is located in one piece just above the brake main cylinder. Brake hydraulic oil is stored inside and the oil needed by the brake system is drawn from here, the oil returning from the system returns to this tank.

Brake Limiter (Brake Pressure Proportioner Valve): The brake limiter is used in old type vehicles without ABS braking system. Braking pressure generally needs to be sent 70% to the front wheels and 30% to the rear wheels; Because the engine is in front and the weight of the vehicle is on the front wheels during braking, the front wheels of the vehicle need more brake pressure and the rear wheels need less brake pressure. This hydraulic valve, which reduces the pressure of the brake fluid to the rear wheels when the brake is applied, is called the brake limiter.

Load sensitive brake limiter is used in order to increase the brake pressure sent to the rear wheels according to the amount of load in vehicles such as load-carrying trucks and pick-up trucks. This is also called brake regulator.

Disc Brake Mechanism: This is the part where braking occurs. Pressurized brake fluid coming from the brake main center acts on the piston in the caliper, the piston moves forward with pressure and presses the brake pad in front of the brake disc, and the disc-wheel slows down or stops as a result of friction. In new generation passenger cars, disc brakes are used on both the front and rear wheels, however, disc brakes at the front and drum brakes at the rear are very common in passenger cars and light commercial vehicles. For more information (See: Disc Brake System)

(Disc Brake Parts and Drum Brake Parts)

Drum Brake Mechanism: The drum brake mechanism is generally used on the rear wheels of commercial vehicles (trucks), passenger cars and light commercial vehicles. With the effect of the hydraulic oil sent from the brake main center to the brake cylinder located on the brake plate, the pistons in the cylinder open to both sides and press the brake shoes with brake pads against the drum, thus braking is realized. The brake pad also contains the handbrake mechanism.