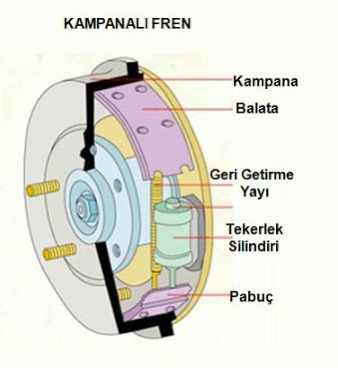

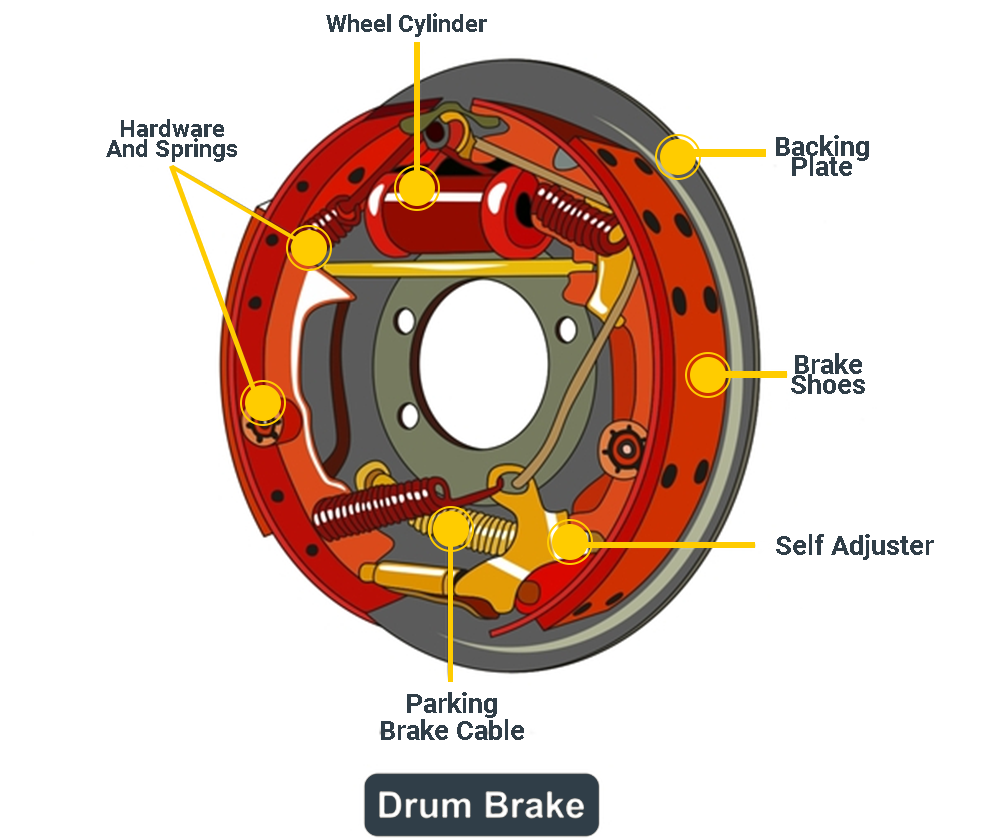

What Are Brake Drum System Parts?

The brake drum system consisting drum, wheel brake cylinder (brake center), pistons inside the brake cylinder, shoes, pads, return springs. In addition, the handbrake mechanism is located on the brake plate. Drum: It is a metal part, usually made of cast iron, that rotates with the wheel. It is mounted on the wheel hub with lug studs. The inner surface of the drum forms the friction surface of the pads.

Wheel Brake Cylinder: This is also called the brake center in the industry (not the brake master center), the brake hose is connected to the brake cylinder with a union. By converting the hydraulic pressure into a thrust with the pistons inside, it presses the pads to the drum.

Brake Shoes: It is a half-moon shaped metal piece on which the pads are riveted or glued. The piston brakes by pushing the shoes forward, and the return spring retracts the shoes.

Brake Pads: It is the part on the shoes that opens outward with the shoe when the brake is pressed and rubs the drum, has a high friction coefficient and creates the braking effect.

Return springs: These are the springs that open outwards when the brake pedal is pressed and bring the brake shoes in contact with the drum back to their normal position by pulling back when the brake is released.

How Does the Drum Brak eSystem Works?

The drum brake system is the brake mechanism used on the rear wheels of passenger cars and light commercial vehicles and heavy vehicles. The brake mechanism is fixed, the drum rotates with the Wheel. When the brake pedal is pressed, pressurized hydraulic brake fluid opens the pistons (right-left) in the wheel brake cylinder located on the brake plate, pushing the brake shoes towards the drum. The brake pads on the outer surface of the shoes create the braking effect by rubbing against the inner surface of the drum.

Drum brakes are overheat because operate in the closed area and are difficult to cool, when it warms up, the braking force decreases. In addition, since the drum mass is high, it increases the unsprung mass (except the suspension), which has a negative effect in terms of comfort.

Self Braking Effect (Self Servo Effect – Self Energy)

This feature is not available for disc brakes. In addition to the braking force obtained by pressing the brake pedal in the drum brake system; An additional braking effect occurs due to the rotation direction of the drum and the way the pads contact.

While the drum is turning to the left (ie the vehicle is moving forward), the pistons in the wheel brake cylinder open the brake shoes both to the left and to the right when the brake is applied. Since the direction of rotation is to the left, the brake pad on the left tends to rotate together with the drum when pressed against the drum, that is, it creates a pressure in the direction of friction in addition to the brake thrust, thereby creating a self-braking effect and increasing the braking force of the vehicle. Because of this extra braking, the left pads generally wear out more than the right pads.

At the same time, the brake pad on the right is also pressed to the drum, but here, the opposite of the above logic; The drum shows a pushing effect against the lining, which acts in the opposite direction due to the direction of rotation. For this reason, the brake pad on the right side has less braking effect and wears less than the pad on the left.

Types of Drum Brake System

Various designs are used in drum brakes with double cylinder (one on top and one on the bottom), single cylinder (only on the top), single acting cylinder or depending on the structure of the studs of the shoes. The most used drum brake type: single cylinder and self-adjusting type.